Smartvision

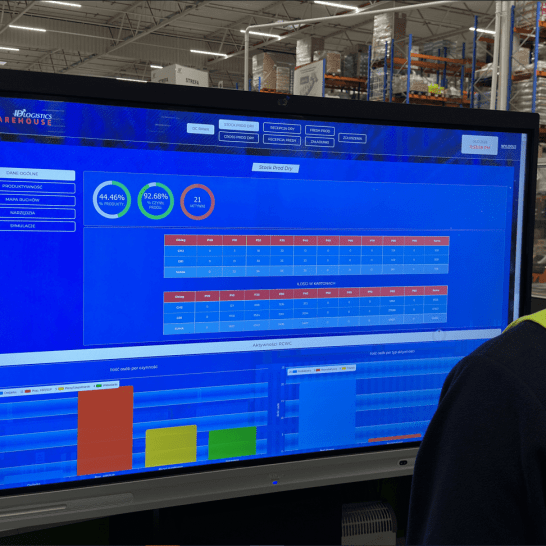

Smartivision is artificial intelligence at the service of zero-defect preparation thanks to data filmed by stereovision cameras. Smartvision reduces the error rate by 80%, digitizes the team leader’s position and enables to monitor the preparation of parcels by operators in real time.